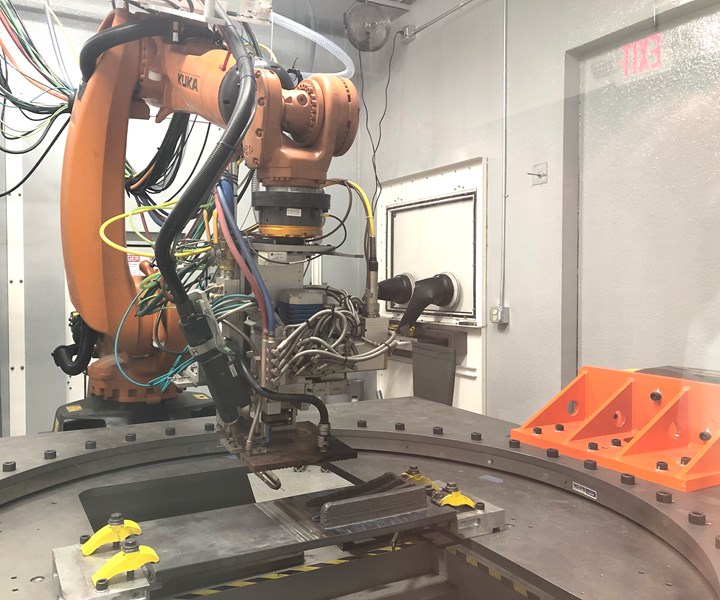

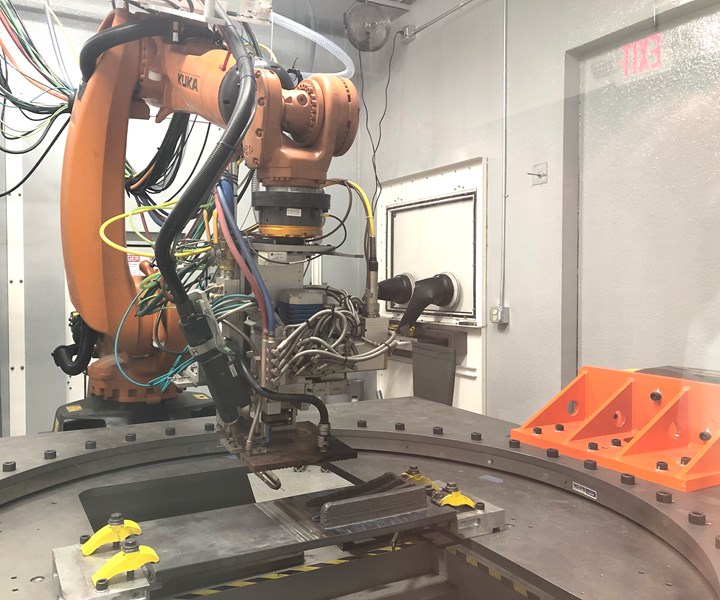

Robots can stretch 3D printers, but they can also be used to handle the print head. Here, the Addere system deposits a weld wire using a laser head mounted on a Kuka robot.

Robots and additive manufacturing (AM) are both processing technologies, with the potential to reduce labor, reduce costs and disrupt the way products are manufactured. But what happens when these two technologies work together?

In the history of coverage, Evco Plastics explains the process to integrate these universal cobot robots with its 3D printers. Learn more.

The July 2019 issue of Additive manufacturing The magazine explores how robots and AM meet in various ways. In our coverage, injection Molder Evco Plastics shares its experience by integrating a cell of six 3D printers with a collaborative robot (COBOT). The work that the COBOT does (eliminate construction plates with finished parts and starting the following cycle) is similar to how it could serve a machine-tool, but the integration process required ingenuity and creativity . EVCO now has an automated unit which can operate 24/7, giving this company the ability to take production work which would have previously been prohibitors of injection mold.

But unloading parts is not the only way to participate in robots. The other stories of this issue include:

- The 3D metal printing system based on the Addere robot (illustrated above) uses a standard weld wire to build large parts, with a deposit rate which can reach 50 lb / h.

- Research on the “swarms” of robots could allow a new ultra-efficient 3D printing and automated manufacturing era.

- A San Diego startup explores multimaterial 3D metal printing and new ways of thinking about laser metal (LMD) deposit deposit technology, now compatible with robotics.

- The personalized 3D printed pliers made internally allow Bilstein of America to get the most out of its cobots.

Read it here And get down To receive the next issue in your mailbox or your reception box.

Additive conference conference

This issue also includes an overview and a guide to the Additive Manufacturing + Expo conference, a three -day technical conference, an exhibition hall and a commercial networking event focused on industrial applications of additive technologies for production. Register here.