✕

With more industries adopting robotic systems to provide greater efficiency and productivity, the need to ensure that employees are safe around robots have never been higher. For over 40 years, the Association for the progress of automation (also known as A3) played a leading role in the guarantee that the robotics industry continues to proactively assess the safety environment and provide security resources as the robotic applications become more advanced, more competent and more popular.

Not only A3 hosts the International Robot Safety Conference Each year, but since 1982, A3 has supported the security of industrial robots as an organization of standards development (SDO) for the American (ANSI) and international (Iso) organizations. We sat with Carole Franklin, director of standards development in A3, to talk about the importance of safety standards for robot systems and the various requirements necessary to guarantee safe deployments.

What are the security standards for robots and why are they so important?

A robot safety standard is a collection of requirements for robot specifications and safe operations that all people involved in the manufacture, sales and use of robots must follow. Having a standard set of international directives allows easier use and sales of robots, stabilize markets and encourage the growth of robotics as a whole.

How are robots safety standards different from government regulations?

Unlike government regulations, standards are developed by a volunteer committee of industry experts on a given subject. The objective is that a wide range of interests have a place at the table and has a good chance of making their voices heard. This also gives participants the opportunity to show that they are capable of an effective self-government on the subject. With regard to robot safety standards, the subject of “workers’ safety around industrial areas” is crucial. The more we show an effort in good faith to follow the best practices collected in this area, the more our regulatory agencies can govern us with a lighter hand.

Industry standards are also updated more frequently than government regulations. This allows industry standards to treat the acceleration of technological advances, such as the growing popularity of collaborative and mobile robots. These updated standards allow us to move away from historical advice designed to keep people from robots away from new advice that is suitable for ensuring people with robots. Although membership of these standards is often not required by law, standards provide an effective framework for workers’ safety.

Does a safety standard cover all robots or are there different standards for different types of robots? If several, what are the differences?

Although the ultimate objectives are similar – to ensure the safety of people near robot systems – there are different safety standards with unique requirements for the type of robot systems deployed. Conventional robots which are generally behind a fence or another speaker, and collaborative robots, which are designed to operate safely alongside human workers, are the robot systems covered in the flagship standard of A3, ANSI R15 .06, which is a national adoption of ISO Standard 10218 security for deployments of conventional and collaborative robots.

Vision and sensors

A Quality Special section

The problem of safety of conventional robots systems has been to restrict the physical access of people to potential dangers. The standard defines the maximum space which can be reached by the mobile parts of the robot application, including the final effector and the part. Restricted access is generally obtained by surrounding the maximum space in a backup space, with a fence to prevent people from getting out, or guarantees such as a light curtain or a press that detects a person in The space and brings the robot system to a sure stop to stop.

Although standard R15.06 allows collaborative and mobile operation for conventional robot systems, it does not explain the safety requirements for these types of installations. The next edition of R15.06 will include security requirements for the collaborative functioning of robots, which the standard defines as a “state in which robots designed on purpose work in direct cooperation with a human in a defined workspace”.

For these collaborative deployments, users must understand the distinction between robot and robot systems. Integrators and users should determine if the whole robot system, not just the robot, is “collaborative”. For example, industrial robots called “collaborative robots” represent only the collaboration of power and limitation of force (PFL). Other types of collaboration, such as speed and separation monitoring (SSM), can be implemented using non -PFL or conventional arms robot.

To ensure the safety of collaborative robot systems, users should consider these practical steps:

- Understand the relevant standards: R15.06 / ISO 10218 and technical report RIA TR 606 / ISO TS 15066.

- Consider the robot system as a whole, not just the robot arm.

- Select equipment such as the final effects in order to avoid everything that presents a security risk.

- Always carry out a risk assessment (RIA TR R15.306-2016 provides advice and models related to the risk assessment methodology based on tasks).

- Look at the robot poses and the paths to avoid situations where a person could be injured, in particular involving contact with the face / head / neck or tightening / pinching.

What about standards for mobile robots? And what steps are necessary to ensure a safe deployment for these types of robots?

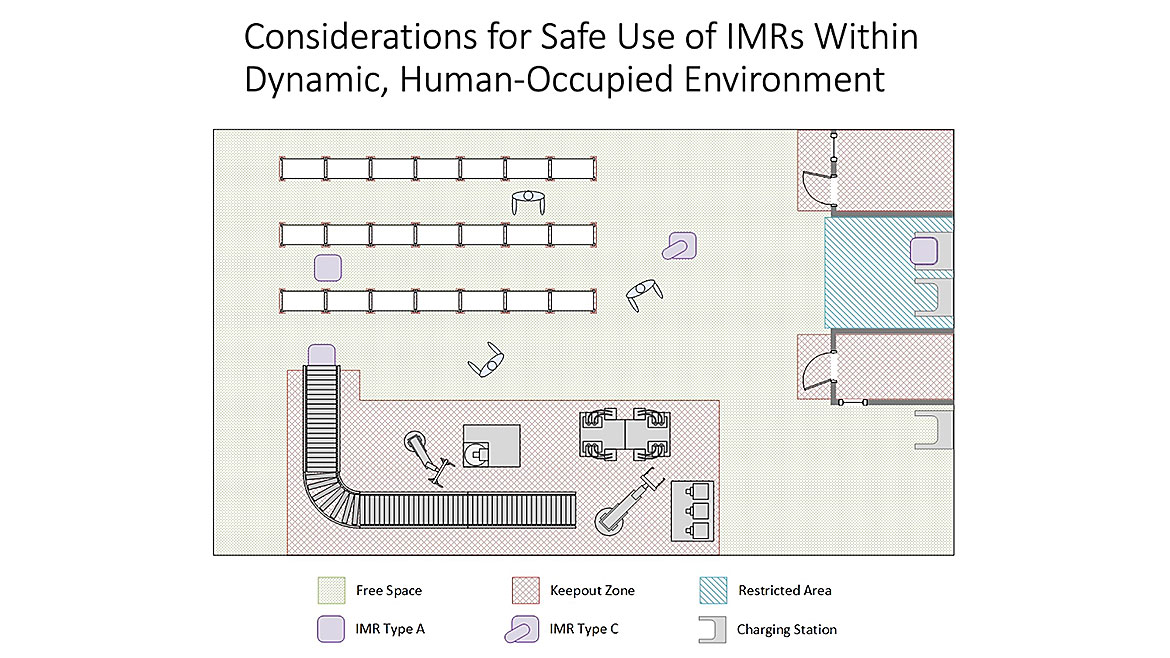

At the end of 2020, A3 published part 1 of standard R15.08 ANSI to establish security requirements for industrial mobile robots (IMR) as guidance for robot manufacturers. Part 2 of R15.08, which has just been approved, establishes security requirements for the deployment of IMR systems in an industrial environment, in particular the integration, configuration and personalization of the IMR or the Fleet D ‘IMR in a site.

Safety advice for IMRs continue to evolve with new technologies and use cases. The most important step is to consider the whole environment mapped – a state of mind different from that of a fixed robot cell or an automated guided vehicle (AGV). The integrator must assess the entire installation where the IMRS will operate and manage the operating environment deployed (DOE). Since the IMR system could be deployed in an existing installation, the DOE may not correspond to the specified operating environment (SOE) provided by the IMR manufacturer, it could therefore require attenuation plans dangers resulting from inadequacy. The layout analysis must intentionally design the interactions between IMR and workers as well as between IMR and mooring or load stations.

As with standards R15.06 / 10218, risk assessment remains an essential element for the safe deployment of mobile robots, especially when they are not limited to a defined path. Standards provide important advice on requirements such as protection and emergency stops, collision prevention, speed control and stop distance, as well as cybersecurity problems.